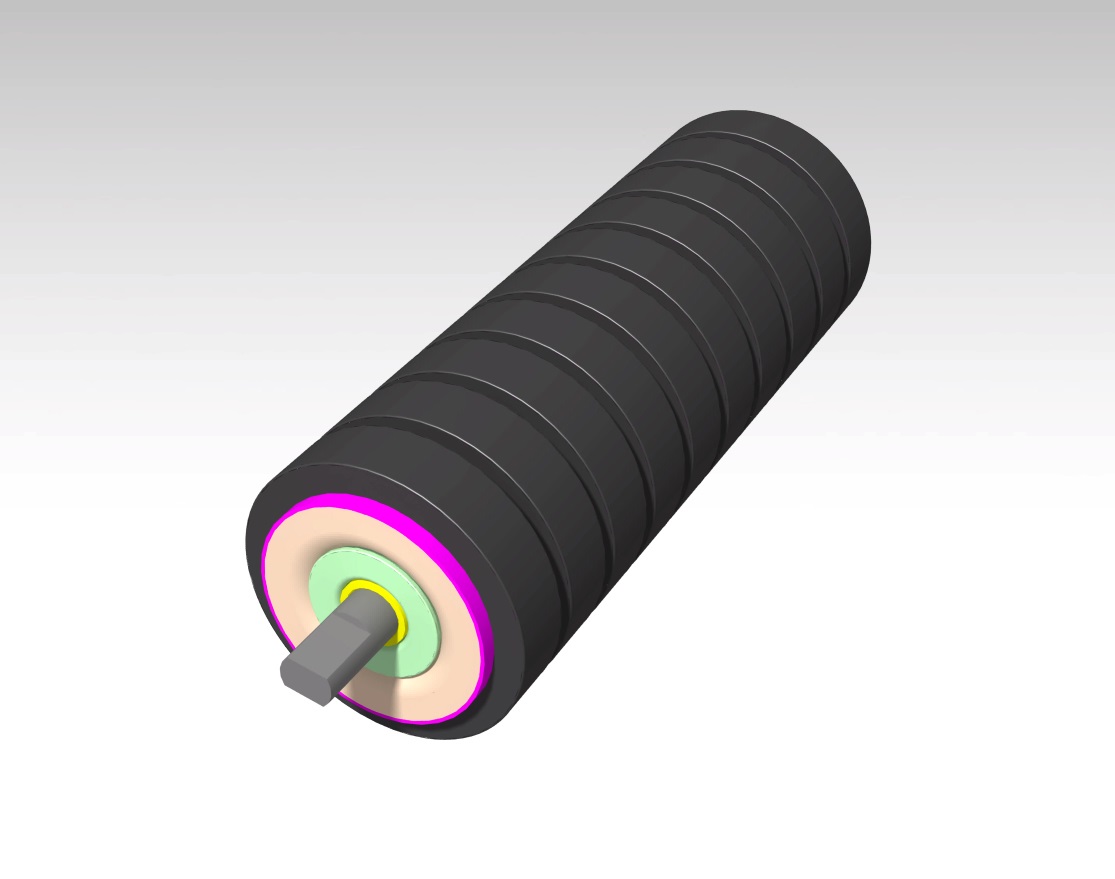

- Pipe: from 63 to 108 mm diameter (ST37)

- Shaft: from 20 to 30 mm diameter (ST37, CK45, MO40, 304)

- Bearing: 6204, 6205, 6206

- Shaft type: A2, B2, threaded, flat screw, hooked and…

- Paint: electrostatic and oil spray

- Exclusive P6 seal and metal cap

- Tires: from 55 to 80

rubber roller (shock absorber)

Short description:

rubber roller (shock absorber)

Impact rollers (rings) are rollers carried from the upper belt of the belt, usually used to absorb and dissipate the energy of the falling load at loading points. Due to its high flexibility, the rubber disc prevents damage to the pipe, belt and load.

What is a rubber roller?

The rubber roller (impactor) is one of the main and important components of the conveyor, whose main task is to absorb and destroy the load at the loading points. Due to their high flexibility, shock absorber rollers prevent impact and damage to the belt. To learn more about this part, in the rest of the article, we are going to examine the advantages and use of the rubber roller or the impact roller in the conveyor system.

Getting to know how the conveyor belt works and the role of the rubber roller in it

Before we want to examine the application of the rubber roller, it is better to familiarize yourself with how the conveyor system works. Conveyor belt is a transport system and it is used to transfer parts and materials from one point to another. The transfer action on the conveyor belt usually takes place in two ways, horizontal and straight or inclined.

You can see its horizontal example next to the cash register of big stores. The same part where you put the things you bought. In general, it can be said that using a conveyor makes it very easy to transfer and move items.

The conveyor belt consists of various components, which are:

• Belt or tape: The belt is the main tape on which parts or materials are placed and moved.

• Rollers: The role of rollers is to move the conveyor belt or rotate it.

• Drive motor: provides the power required to move the conveyor.

• Gearbox: It is responsible for changing the speed of the engine and bringing it to the desired speed.

• Belt tensioner: This part of the conveyor belt system is responsible for adjusting the belt tension and usually works mechanically.

Therefore, it can be concluded that the rollers, especially the rubber roller, are one of the essential parts of the conveyor system and without it, the conveyor will not be functional.

Getting to know the roller and introducing its different types

It is better to know that the roller is not only limited to the rubber roller, but there are different types, each of which performs a specific task. For this reason, they are very different from each other in terms of shape and gender. In general, it can be said that the rollers are one of the equipments in the conveyor belt that prevent friction in the belt and play a very important role in saving energy. In the following, we will get to know some types and applications of different rollers.

• Rollers: These rollers are installed on the side surfaces of the conveyor belt and bear the weight of the transfer material and the conveyor.

• Return rollers: This type of roller is installed on the lower levels of the conveyor and its task is to bear the weight of the belt when moving the load.

• Impact rollers: These rollers are installed on the belt at the places where the material falls to prevent excessive force from being applied to the belt.

• Pressing rollers: these rollers are designed and made in the form of pressing, and therefore its parts cannot be easily replaced. Among the parts of the roller press, we can mention bearings, shafts and felt bowls.

• Guide roller: this type of roller is installed next to the conveyor and is responsible for guiding the conveyor.

Getting to know the rubber roller and the reason for using it

A rubber roller is a welded steel roller that has a special rubber attached to it with pressure. The rubber rings used in these rollers are anti-wear and therefore do not get damaged due to wear.

If you look closely at conveyor systems in airports or stores, when something is placed on the conveyor, its weight is transferred to the belt. Now, if this weight is not controlled, the belts will lose their useful life and get damaged in a short period of time. For this reason and to prevent the belt from being hit, impact rollers are used to restrain the weight of the goods.

They also use rubber rollers in factories and places where there is a risk of falling loads. It should be noted that in each conveyor belt, the size of the plastic cover of the roller must be the same as the roller.

Which industries use rubber rollers?

Rubber roller is used in many industries, including the following industries.

• Cement, lime and plaster industries

• Steel making, casting and smelting industries

• Types of metallic and non-metallic mineral mines

• Pipe making industries

• Sand and coal mines

Rubber roller quality control tests

Since rubber rollers play a very important role in transmission lines, if they fail, the entire system will fail. Therefore, various quality control tests should be performed on them to ensure their correct performance. These tests include:

Roll balance test

When we install the roller on the conveyor, it should be balanced with other parts such as the balance roller. Because otherwise the belt will not move properly. Roller balancing is done according to ISO1940/1 standard.

Rubber roller sealing test

The most important test that is performed in the roller quality control stage is the sealing test. Because the conveyor belt is usually installed in dusty environments. Therefore, the roller should be insulated against these materials, especially water. For the sealing test, the roll is first weighed and then it is measured

They put it under water for 2 hours. After that, they weigh the rubber roller again. If the difference between these two weights is more than 10 grams, it means that the roller does not have the necessary sealing.

Friction test

The next test that is performed on the rubber roller is the friction test. The lower the friction of the roller, the longer its useful life will be. According to the standard, the friction coefficient of the roller should not be more than 0.0250.

welding test

Connecting different parts of the rubber roller to each other is done by welding. If the welding operation is not done correctly, the roller will fall apart during operation and disable the entire conveyor belt system. Therefore, non-destructive welding testing is very necessary.

The price of a rubber roller

Many factors play a role in determining the price of a bumper roller, and a fixed number cannot be considered for it. That is why the price of this piece varies among brands. The factors that affect the price of a rubber roller are:

1. Roller size and diameter: Size is one of the important factors in determining the price of a rubber roller. In fact, the bigger the size of the roller, the more parts it uses. As a result, its price also increases. In order to reduce the final price of the product, some companies use low-quality raw materials and parts, as a result of which the efficiency of the part also decreases; Therefore, to buy basic and important parts, consider the quality.

2. Roller material: The next factor in determining the price of a rubber roller is the type and material used in it. Since this part plays a very important role in the conveyor, its material is also very important. Of course, be careful that the metal used in the roller must be compatible with the weather conditions of your region. Also, plastic materials should be made of materials that can show good resistance against wear and heavy weight.