- Pipe: from 63 to 108 mm diameter (ST37)

- Shaft: from 20 to 30 mm diameter (ST37, CK45, MO40, 304)

- Bearing: 6204, 6205, 6206

- Shaft type: A2, B2, threaded, flat screw, hooked and…

- Paint: electrostatic and oil spray

- Exclusive P6 seal and metal cap

- Tires: from 55 to 80

- interface ring: polyethylene PE

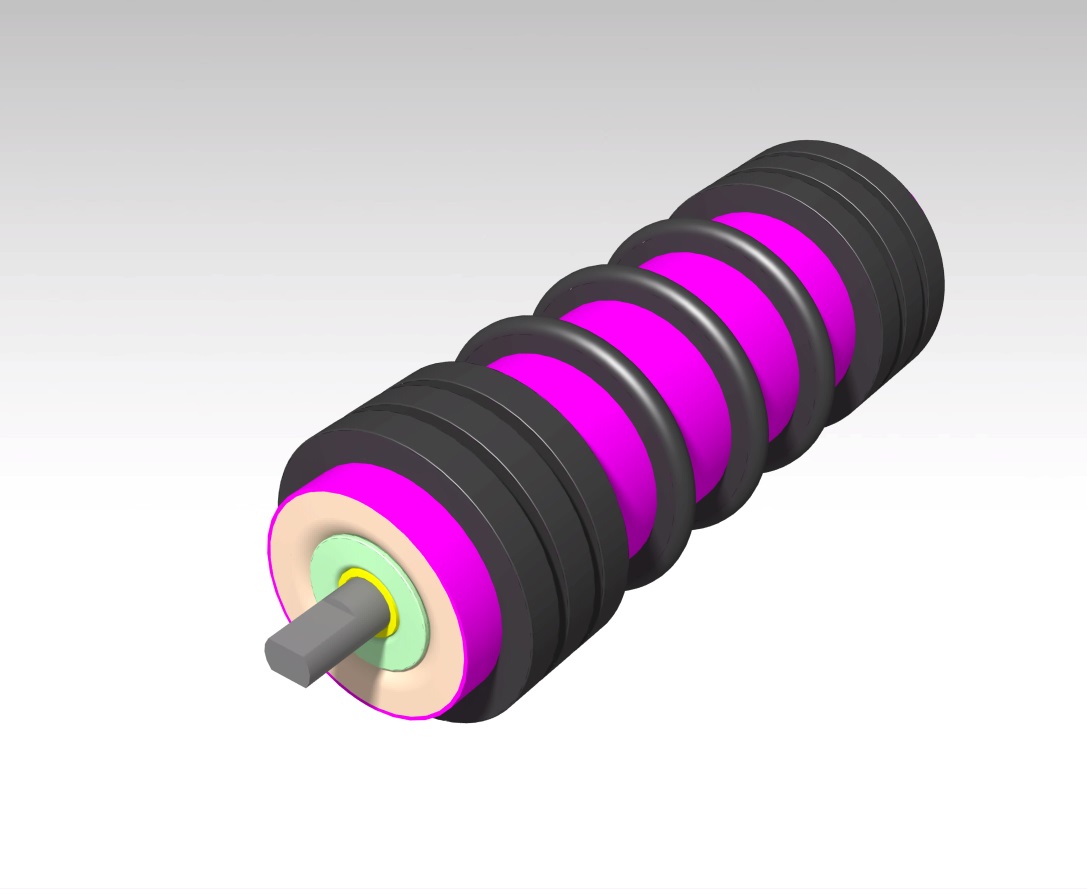

Disc roller or back roller

Short description:

Disc roller or back roller

Disc rollers support the under or return belts and apply a lower band of conveyor belt underneath and remove continuous material from it. The return roller is made of a coated steel tube in which rubber or polyurethane rings are mounted.

One of the main parts used in conveyor belts are rollers. These parts play a very important role in industry and material transfer. In fact, rollers are moving rollers that transfer items through a conveyor belt or a conveyor system. Since this part has different uses, therefore, different types of it have been designed and made, each of which performs a specific task. Among these types, we can mention the return roller or disc roller, which we will learn more about later.

What is a return roll or disc roll and what is its function?

Before entering the main discussion, it is better to get acquainted with the conveyor belt and the duties of the roller in it. Because this issue can play a very important role in understanding the task of the back roll or disc roll. In various industries, a device called a conveyor belt is used to transfer materials and products from one point to another. In fact, the conveyor belt is a moving plate made of metal or rubber that is moved by a motor and gearbox. If we want to give a clear example of a conveyor belt, we can mention an escalator.

Now, in order for objects to move easily on this belt, they have used a piece called a roller, and in fact, without a roller, there would be no conveyor belt. It is better to know that different types of rollers are used in a conveyor, each of which has a special task. Some of these roles are:

Rolled roller: This type is used to bear the weight of the belt.

Impact roller: This roller is used to keep the tape stable and prevent it from being damaged.

Return roller or disk roller: This roller is installed on the lower surface of the conveyor belt and is used to bear the weight of the belt during return.

Apart from these three cases, there are other types of rollers that are the most efficient.

The function of the return roller or disc roller is to return the belt to the starting point, and therefore it is installed under the conveyor frame and helps the belt to go back. In the design and manufacture of the return roller, plastic rings are used so that the amount of wear reaches its minimum value. Because there are very small particles on the conveyor belt that can increase wear and friction. When they use plastic, this abrasion is reduced. Also, the material of the return roller should be such that it can withstand high pressures. For this reason, the material of the body of this roller is made of strong metal.

Examining the importance and application of the return roller or disc roller

As we mentioned above, the return roller or disc roller has a very important role in the conveyor belt and if this roller is damaged for any reason, a lot of pressure is applied to the conveyor and as a result, the belt may be damaged very soon. . In fact, in addition to helping the movement, the back roller also plays a very effective role in bearing weight.

The use of return roller or disc roller is used in various industries. For example, it is used in airports to carry luggage. In order to be able to withstand the weight of these loads, the roller must be made of good material and well sealed. If this roller does not have a standard design, it will have a very short useful life and as a result, you will have to pay for it again.

Quality control tests of return roll or disk roll

Since the damage of the return roller can cause the complete stop of the conveyor belt, it is better to perform various tests and quality control on it to find out whether it meets the required standards or not. Among the tests that are performed in Asarol on the return roller, the following can be mentioned.

Sealing test: The return roller is always exposed to dust and pollution. If these materials can penetrate into the roller, its parts will wear out and break down very quickly. Therefore, this part should have good resistance against suspended dust particles. For the sealing test, the roller is first weighed and then placed in water. If its weight does not change after 2 hours, it means that the roll has successfully passed the test. Of course, there is no problem with a weight difference of less than 10 grams.

Balance test: Another test that is performed on the return roller or disc roller is the balance test. This test is performed based on the ISO 1940/01 standard and the roller must be able to be balanced and aligned.

Welding health test: The different parts of the return roller are connected by welding. If the welding is not done well for any reason, the parts will separate and the system will fail.

Types of return roller or disc roller

The return roller or disc roller is usually designed and made in two horizontal and V ways, and the V type is very suitable for bearing heavy loads. Of course, sometimes you may have to order a return roller or a unique disc roller due to the needs of the project. The reason for this can be due to different climatic conditions or high load.

The price of a return roll or disc roll

The size and material used in the roller are among the influential factors in determining its price. That is why the sellers announce different prices for this piece. But in addition to these two

For example, there are other factors that are effective in determining the price of a return roller or a disc roller, which we will learn more about.

The return roller is made of iron or steel; Therefore, if the price of these two increases, the price of the roll will also increase.

The next factor in determining the price of the return roller is the type of parts used in it.

Another thing is the quality of making the return roller. For example, if high-quality bearings and rims are used in making the roller, the final price will be much higher.

Therefore, if you intend to get the price of the return roll day, it is better to contact Asarol experts through the contact numbers on the website so that they can inform you of the exact price.

Buy a roller from Asarol

Using the latest equipment and the best materials, Asarol produces and markets all kinds of return rollers or disc rollers. In addition to producing high-quality parts, this collection has made every effort to provide them at a reasonable price to our dear customers. Therefore, buying a roller from Asarol can play a very important role in the efficiency of the conveyor and reduce your costs.